Rendering was much the same as the technique used in previous modelling modules. The slight change was that this time we rendered the 3D Studio Max file into TAGA images. This meant that if there were any errors at a certain frame we could re-render from that frame rather than the entire animation.

We set the output to HDTV (720x1280) in order to get a nice quality resolution and put the output images into a single file for the sake of ease.

Wednesday, 5 December 2012

Narration

At this point I had to get my David Attenborough on. The script was just factual information that we found but the voice over adds some extra information to our scenes.

We recorded onto a phone and then uploaded the clips to Premiere Pro for editing.

We recorded onto a phone and then uploaded the clips to Premiere Pro for editing.

Blowing in the Wind

This scene was of the attack rumour document being "misplaced".

The document started as a simple plane with the document applied as a texture. The plane was then given the texture of spandex. This was a preset and set up the plane to react as spandex would when outside forces, such as wind, acted upon it.

We then added wind into the scene and sampled the animation. Although the document reacted it took various attempts, changing the wind speed, direction and turbulence in order to make the document react as required. Once the paper was flying properly we had to cheat slightly by having to move the window into its path but it turns out that shooting a piece of paper through a window using nothing but wind is remarkably difficult.

The document started as a simple plane with the document applied as a texture. The plane was then given the texture of spandex. This was a preset and set up the plane to react as spandex would when outside forces, such as wind, acted upon it.

We then added wind into the scene and sampled the animation. Although the document reacted it took various attempts, changing the wind speed, direction and turbulence in order to make the document react as required. Once the paper was flying properly we had to cheat slightly by having to move the window into its path but it turns out that shooting a piece of paper through a window using nothing but wind is remarkably difficult.

The Man in the Office

This was the first meld of components created by different members of the team. The office, created by me, and the soldier created by Mel. In this scene the soldier is seen walking into the office and using the Morse Code Machine.

In order to make him walk the Footstep Mode was used to make the biped walk around the office. Initially a set number of footsteps were placed simultaneously and then once the figure was close enough to the seat footsteps were placed individually in order to get it into the correct position to sit.

Once the biped was correctly placed to sit a new layer was created in the animation, as extra animation cannot be created after the footsteps have stopped on that layer. On this new layer I moved the biped so that it was sitting and using the morse code machine. This layer was set to become visible after the walking layer had finished.

In order to make him walk the Footstep Mode was used to make the biped walk around the office. Initially a set number of footsteps were placed simultaneously and then once the figure was close enough to the seat footsteps were placed individually in order to get it into the correct position to sit.

Once the biped was correctly placed to sit a new layer was created in the animation, as extra animation cannot be created after the footsteps have stopped on that layer. On this new layer I moved the biped so that it was sitting and using the morse code machine. This layer was set to become visible after the walking layer had finished.

Models - The Office

After having completed all the office equipment models, it was time to build the office itself.

You guessed it, the box! This time the faces were flipped and a backface cull was applied so that the interior of the room could be seen from every angle without having to delete walls. This was looking toward insertion of cameras for the animating stage. It the walls were deleted then they would always have to kept out of shot but with this option applied the camera could move more freely.

Then it was just a case of populating the room. A window was added and a door complete with door knobs. Because the division between floor and wall was very sharp, a skirting board was also added. Once the rookm itself was ready and textured then furniture was added. A simple table was built as well from boxes on which the other furniture was placed.

You guessed it, the box! This time the faces were flipped and a backface cull was applied so that the interior of the room could be seen from every angle without having to delete walls. This was looking toward insertion of cameras for the animating stage. It the walls were deleted then they would always have to kept out of shot but with this option applied the camera could move more freely.

Then it was just a case of populating the room. A window was added and a door complete with door knobs. Because the division between floor and wall was very sharp, a skirting board was also added. Once the rookm itself was ready and textured then furniture was added. A simple table was built as well from boxes on which the other furniture was placed.

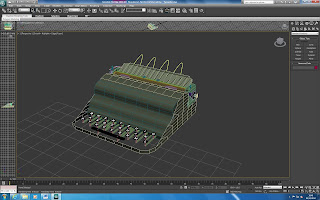

Models - Typewriter

As with every other model, the trusty box was the starting point. The polygons of this box were then deleted in order to form a basic shell for the typewriter. Once the basic shape was formed the polygons and vertexes were then fine tuned to form rounded edges and other similar details.

After the shell of the typewriter was complete, it was then time to fill it with all the typewriter-y bits. These started as a simple box that was moulded into the curves of the top/front of the model. This was again achieved through editing the vertexes.

Once the body of the model was in place and shaped properly, the roller was inserted. This was a cylinder the every other polygon on one end extruded inwards to form a cog. Then to make a change in the texturing the next row of polygons had their texturing number changed so that it formed a seam between this row and the ones next to it.

Finally the tray at the back was formed in a similar way to the wires in the previous two models.

The knobs and wheels were also added in a similar way to the ones in the previous models. Thankfully the potentially most time-consuming part of this model, the keybourd had already been done and could just be imported from the Enigma Machine model and placed.

When applying textures to this model it followed a similar patteren to the previous constructions as they all used reasonably simialr materials.

After the shell of the typewriter was complete, it was then time to fill it with all the typewriter-y bits. These started as a simple box that was moulded into the curves of the top/front of the model. This was again achieved through editing the vertexes.

Once the body of the model was in place and shaped properly, the roller was inserted. This was a cylinder the every other polygon on one end extruded inwards to form a cog. Then to make a change in the texturing the next row of polygons had their texturing number changed so that it formed a seam between this row and the ones next to it.

Finally the tray at the back was formed in a similar way to the wires in the previous two models.

The knobs and wheels were also added in a similar way to the ones in the previous models. Thankfully the potentially most time-consuming part of this model, the keybourd had already been done and could just be imported from the Enigma Machine model and placed.

When applying textures to this model it followed a similar patteren to the previous constructions as they all used reasonably simialr materials.

Models - The Morse Code Machine

Similar to the Enigma Machine, this model was based upon the basic box shape.

Firstly an indent in one of the faces was created using the Inset and Extrude tools to form the main control panel. This was then fine tuned by editing certain polygons to achieve two curved arches at the top of this panel.

The buttons were then created and placed. They were built using cylinders mostly. Some had curved tops which were created by pulling up the vertexes on the top face of the cylinder to make it curved (this technique was also used to elongate some of the buttons). These knobs then had every other face around the sides extruded and bevelled to form the rough grip for them.

Then came the plugs for the wires. These were cylinders with the outermost ring of polygons selected and then extruded to form the sides of the plug. Within then plug itself, pins were placed made from capsule shapes.

Once all the plugs and sockets were built and placed, readout was constructed by extruding a flattened cylinder. Firstly the vertexes had to be edited so that the extruded portions formed the shape of the glass panel on the reader. Once the vertexes were correctly positioned the faces that were to be extruded were selected and then modified. This produced and correctly shaped indent but the readout has glass on it. To put this in the section of the readout that had been extruded was selected again and duplicated. a material was then added to this section that was created by reducing it's visibility and increasing it's glossiness to mimic glass. The duplication of this section also meant the glass panel was a perfect fit.

Similarly, this glass texture was used for two similar inclusions either side of the main readout. For these a rectangle was textured and bent.

A second, smaller model formed the device with which the operator taps out messages. This was again another box except that it's edges were modified in order to make them more curved. This was done by moving the vertexes to from a more rounded edge. As for the button on top, this was a flattened cylinder, again with the vertexes moved to form a rounded edge.

The cable connecting the receiver and the smaller tapping box was made in the same fashion as the wires on the Enigma Machine model.

As with the Enigma MAchine model, screws were added to this machine to add to the realism of it.

The Model was them textured using the Material Editor both for creating custom textures by changing the glossiness, colour, gradient, bump, noise setting etc.

Firstly an indent in one of the faces was created using the Inset and Extrude tools to form the main control panel. This was then fine tuned by editing certain polygons to achieve two curved arches at the top of this panel.

The buttons were then created and placed. They were built using cylinders mostly. Some had curved tops which were created by pulling up the vertexes on the top face of the cylinder to make it curved (this technique was also used to elongate some of the buttons). These knobs then had every other face around the sides extruded and bevelled to form the rough grip for them.

Then came the plugs for the wires. These were cylinders with the outermost ring of polygons selected and then extruded to form the sides of the plug. Within then plug itself, pins were placed made from capsule shapes.

Once all the plugs and sockets were built and placed, readout was constructed by extruding a flattened cylinder. Firstly the vertexes had to be edited so that the extruded portions formed the shape of the glass panel on the reader. Once the vertexes were correctly positioned the faces that were to be extruded were selected and then modified. This produced and correctly shaped indent but the readout has glass on it. To put this in the section of the readout that had been extruded was selected again and duplicated. a material was then added to this section that was created by reducing it's visibility and increasing it's glossiness to mimic glass. The duplication of this section also meant the glass panel was a perfect fit.

Similarly, this glass texture was used for two similar inclusions either side of the main readout. For these a rectangle was textured and bent.

A second, smaller model formed the device with which the operator taps out messages. This was again another box except that it's edges were modified in order to make them more curved. This was done by moving the vertexes to from a more rounded edge. As for the button on top, this was a flattened cylinder, again with the vertexes moved to form a rounded edge.

The cable connecting the receiver and the smaller tapping box was made in the same fashion as the wires on the Enigma Machine model.

As with the Enigma MAchine model, screws were added to this machine to add to the realism of it.

The Model was them textured using the Material Editor both for creating custom textures by changing the glossiness, colour, gradient, bump, noise setting etc.

Models - Enigma Machine

The Enigma Machine is essentially a box and so this is what the model was based upon. The model incorporated various boxes to form the wooden case in which the machine itself is kept. To form the lid the Extrude and Inset tools where used to form a rim and then push in the underside face. The surrounding edges were simple boxes, measured and them put into place.

The internal mechanism of the machine itself was a cylinder which was then ringed with tubes to form the cog mountings. The cogs themselves were formed from flattened cylinders with every other edge bevelled and extruded to form the spokes. in order for these spokes to be suitably sharp faces were deleted and the gaps bridged.

The dials and buttons where mostly just cylinders with some detailing incorporated using the Extrude tool and Vertex modifier give texture to the standard shapes. For some of the oval shaped dials, a sphere was used, flattened and then stretched into the correct shape.

The keybourd was perhaps the most time consuming aspect of this model. The black bases were simple cylinders coloured black and duplicated for the 26 letters. The letters themselves were simple text that was placed upon each of the keys so that they were in the centre. Each key was then grouped (base and letter) so that when the keys were positioned everything could be moved easily. The positioning was made easier by placing the key stalks first. Once the first was placed it was then duplicated at regular intervals to ensure the proper spacing. Once this was done the keys themselves were then placed on top and centred.

Next came the texture. For the casing a worn wood texture was taken from the Internet and Bump added to it, providing a realistic texture. This material was then placed onto the box exterior. Unfortunately the incorporated worn edge did not fall upon the side that it was meant to. To correct this, the UVW Mapping modifier was used that made it possible for the texture to be fitted to the shape and moved into the correct place through manipulation of the U, V and W channels.

Wood was not the only texture within this model design, plastic and metal were also incorporated as part of the machine's casing and inner working as well as some of the controls. 3D Studio Max incorporates certain pre-set textures that provide a great base to work with with regards to these materials. They are accessed through assigning the renderer to be Mental Ray and then entering the Material Editor. Within this menu the various material templates can be accessed and then refined for based upon the user's needs.

For this model a brown platic was needed for the inner casing of the machine. A plastic pre-set was selected then tweeked with regards to colour, glossiness and distortion until the resultant material was suitable for application to the model. A similar technique was used for the metal textures used within this model.

Finally a little more detail was added to the model with addition of screws that were simply fattened spheres with two lines of polygons removed from one side and then the subsequent hole filled. They were simple to make but their addition lends that much more realism to the model.

Additionally, the wires at the front were added by creating a compound object from a spline and a cylinder, this allowed for the wires to all curve differently but also have substance and texture applied.

And there you have it, one Enigma Machine.

The internal mechanism of the machine itself was a cylinder which was then ringed with tubes to form the cog mountings. The cogs themselves were formed from flattened cylinders with every other edge bevelled and extruded to form the spokes. in order for these spokes to be suitably sharp faces were deleted and the gaps bridged.

The dials and buttons where mostly just cylinders with some detailing incorporated using the Extrude tool and Vertex modifier give texture to the standard shapes. For some of the oval shaped dials, a sphere was used, flattened and then stretched into the correct shape.

The keybourd was perhaps the most time consuming aspect of this model. The black bases were simple cylinders coloured black and duplicated for the 26 letters. The letters themselves were simple text that was placed upon each of the keys so that they were in the centre. Each key was then grouped (base and letter) so that when the keys were positioned everything could be moved easily. The positioning was made easier by placing the key stalks first. Once the first was placed it was then duplicated at regular intervals to ensure the proper spacing. Once this was done the keys themselves were then placed on top and centred.

Next came the texture. For the casing a worn wood texture was taken from the Internet and Bump added to it, providing a realistic texture. This material was then placed onto the box exterior. Unfortunately the incorporated worn edge did not fall upon the side that it was meant to. To correct this, the UVW Mapping modifier was used that made it possible for the texture to be fitted to the shape and moved into the correct place through manipulation of the U, V and W channels.

Wood was not the only texture within this model design, plastic and metal were also incorporated as part of the machine's casing and inner working as well as some of the controls. 3D Studio Max incorporates certain pre-set textures that provide a great base to work with with regards to these materials. They are accessed through assigning the renderer to be Mental Ray and then entering the Material Editor. Within this menu the various material templates can be accessed and then refined for based upon the user's needs.

For this model a brown platic was needed for the inner casing of the machine. A plastic pre-set was selected then tweeked with regards to colour, glossiness and distortion until the resultant material was suitable for application to the model. A similar technique was used for the metal textures used within this model.

Finally a little more detail was added to the model with addition of screws that were simply fattened spheres with two lines of polygons removed from one side and then the subsequent hole filled. They were simple to make but their addition lends that much more realism to the model.

Additionally, the wires at the front were added by creating a compound object from a spline and a cylinder, this allowed for the wires to all curve differently but also have substance and texture applied.

And there you have it, one Enigma Machine.

Subscribe to:

Comments (Atom)